Tire and Rim Compatibility

American Classic clincher tires are compatible with clincher rims that meet current global design standards set by E.T.R.T.O. and fit within the approved rim width range per tire size. We cannot guarantee tire compatibility with rims that do not meet current E.T.R.T.O. standards. To determine if your current rim meets E.T.R.T.O. standards, please contact your wheel or rim manufacturer.

Hookless

DO NOT use tires that include Stage 3 Flat Protection or Stage 3S Flat Protection on hookless rims.

For Tubeless Ready tires, if the tire and rim both meet E.T.R.T.O. standards for tubeless systems, and the tire is placed on an appropriate width rim, the combination is compatible. However, more care must be taken with regards to tire pressure in hookless systems. Tire pressures for hookless systems are lower than hook-bead rim systems.

ISO-TC31-SC10 provides maximum air pressures for each tire width. Those can be found in the Tire Pressure section of our Tire Basics page. Some hookless rims require lower maximum pressures than those provided on this list. Failure to abide by the lowest of these maximum pressures (rim versus ISO listing) can lead to the tire and rim separating and harm to the rider.

When using American Classic tires on hookless rims, the following must be followed:

- Only use Tubeless Ready tires with hookless rims. DO NOT use Tube-Type tires. DO NOT use Tubeless Ready tires with Stage 3 Flat Protection or Stage 3S Flat Protection on hookless rims.

- Only combine tires with the appropriate width rims as set by E.T.R.T.O. (see the chart below)

- Follow all instructions provided by the rim or wheel manufacturer regarding setting up the base tape. DO NOT add more layers of tape to the rim than is recommended.

- Stay below the lowest of the two maximum pressures found for the rim or as suggested by ISO for the tire.

Rim Size

The bicycle industry tends to cling to tradition, and rim sizes are a particular place where the nomenclature can introduce confusion. Rim sizes like 700c, 29”, and 650b come from an era where many countries had their own way of measuring tires and rims. Today there are standards, like E.T.R.T.O., which provide a system that is followed globally. American Classic uses both the traditional and the global standards sizes on each tire.

The E.T.R.T.O. standards are broken into two numbers: the width and the bead seat diameter. An example is 25-622 which refers to a 25mm wide tire designed for a rim that has a 622mm bead seat diameter.

With regard to rim sizes, 700c and 29” are both based on a 622mm BSD rim. Thus, the diameter of a 29” mountain bike rim should be the same as a 700c road or gravel rim. And both 27.5” and 650b are based on a 584mm BSD rim. Thus, the diameter of a 27.5” mountain bike rim should be the same as a 650b gravel or city bike rim. The bicycle industry tends to use 700c, or 650b, when referring to narrower tires and 29”, or 27.5”, when referring to larger volume tires. This is due to tradition.

For a thorough explanation of tire and rim sizes of the past, and why we call them what we do today, see Sheldon Brown's Tire Sizing Systems page.

Compatible Tire and Rim Diameters

Prior to 2018, many American brands were producing rims that had a larger diameter. The intent was to compensate for the wider tolerances of the bicycle tire and rim system at the time and to help non-tubeless tires lock into the rim. Since that time a more precise global standard was set by both E.T.R.T.O. and ISO and all of the tire and rim manufacturers are moving in that direction. That new standard is more precise and provides a safer connection between the tire and rim beads. All of American Classic’s tires meet these new global standards and will provide a secure connection when mounted properly to rims that also meet these standards.

The larger diameter rims mentioned above were already outside of the suggested tolerances and are now fully outside the allowed specifications. Attempts to mount a tire that meets the newer E.T.R.T.O. standards on one of these larger diameter rims will prove difficult. This relates to any tire that meets the newer E.T.R.T.O. standards whether they are produced by American Classic or another brand.

To determine if your rims meet current E.T.R.T.O. standards, or were part of the larger diameter era, please contact your wheel or rim manufacturer.

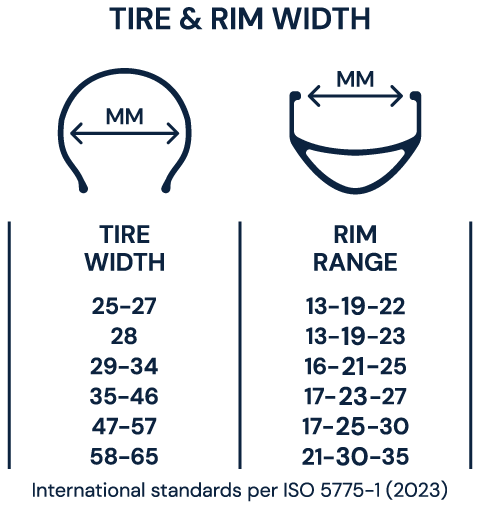

Compatible Tire and Rim Widths

It is important to match the appropriate inner rim width and tire casing size to avoid rim damage, tire roll off, and to optimize performance. Too narrow of a rim for the tire forces the bead to be pulled too close together, the tire tread to be flattened, stability and cornering to suffer, and the risk of tire rolling off the rim while cornering increases. Too wide of a rim for the tire spreads the tire bead too wide moving cornering lugs to the face of the tread, exposes the tire sidewalls to damage, reduces impact absorption capabilities to the point of risking rim damage, and increases the potential of a tire blowing off the rim. Using the correct rim for the desired tire casing size will yield a better performing, longer lasting tire.

American Classic designs our tires using design size standards specified by E.T.R.T.O. and ISO 5775-1. In the illustrations below, the ‘design size’ rim width is the larger number in the center of the rim width range. A tire is mounted to the designated design size rim, inflated, let sit for 24 hours, and then inflated again. At that point the tire will match the listed size. In line with this, a 32mm Torchbearer tire will measure 32mm in width when mounted on a clincher rim that has an internal width of 21mm after 24 hours of inflation. Mounting this same tire on a narrower rim will result in a narrow tire. And mounting this same tire on a wider rim will result in wider tire width.

To determine your rim’s width, measure where shown in the illustrations below.